MARMOX Heavy Board PRO –

for electric underfloor heating

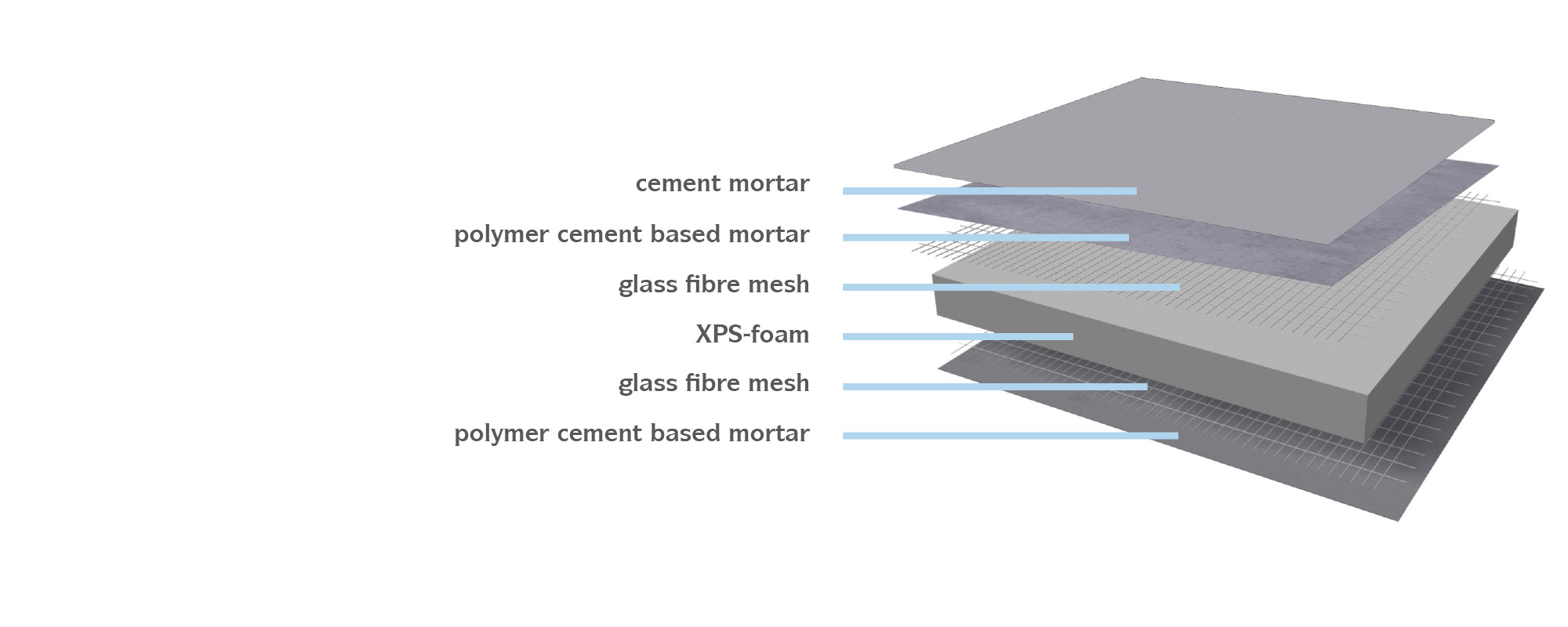

A one side applied additional layer of cement mortar is the special feature of MARMOX Heavy Board PRO. These layer fit with the requirements of a solid non-combustible coating, applied with a minimum thickness, under electric heating wires, as they are known in some countries.

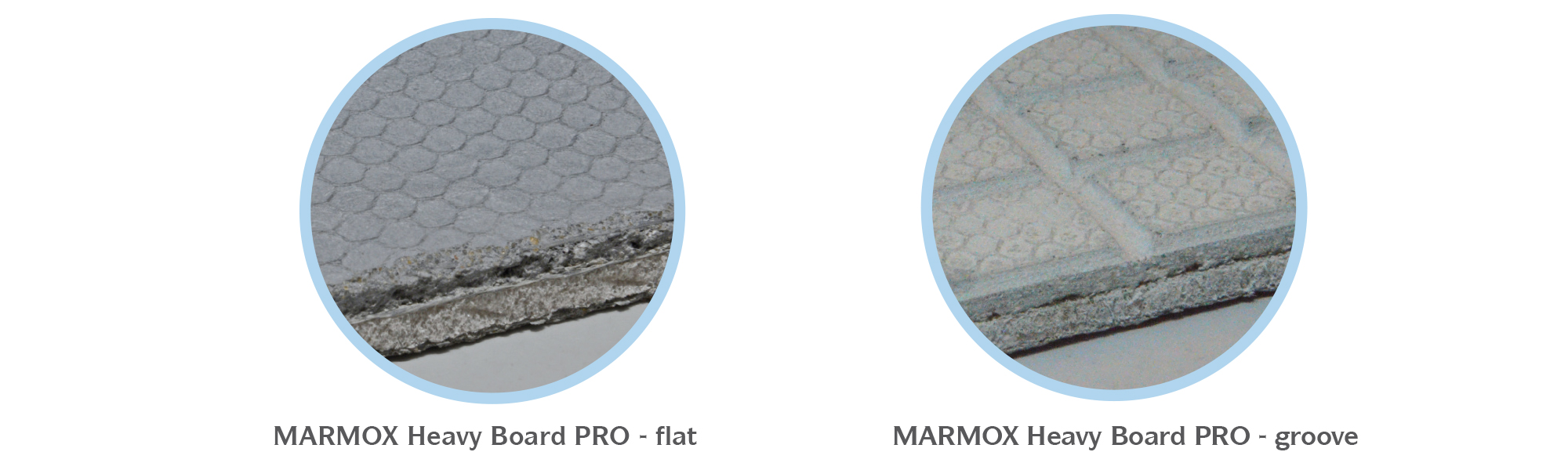

Two types of MARMOX Heavy Board PRO are available, one with a flat surface and alternative with grooves.

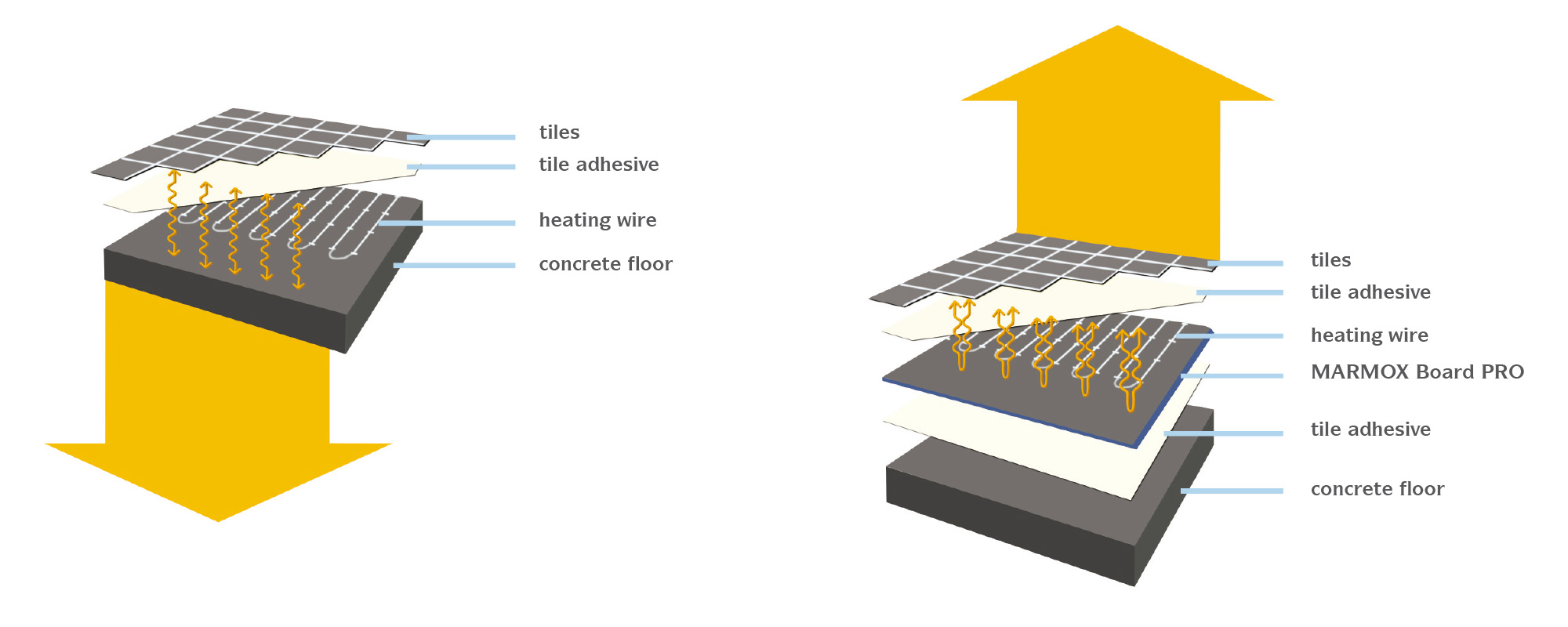

Electric underfloor heating systems are mainly used in bathroom and kitchen. The electric heating wires are embedded in the self-levelling compound or the heating wires, mainly applied direct on the concrete substructure. In that cases 40% of the under floor heating energy gets lost through concrete floors. The results of energy flow to the „wrong“ direction are long reaction time to heat up the floor and non-effective energy consumption. That is a considerable disadvantage of electric underfloor heating system without insulation layer.

Using MARMOX Heavy Board PRO as insulation under electric heating wire, as well as on concrete and wood made substructure, offers two important advantages:

![]() reaction time to heat up the floor temperature will be reduced significant

reaction time to heat up the floor temperature will be reduced significant

![]() the energy consumption will be reduced with increased comfort

the energy consumption will be reduced with increased comfort

Dimensions

Standard dimensions

| Product | Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|---|

| MARMOX Heavy Board PRO 11 – flat | 6 mm + 5 mm Mörtel | 600 | 1.250 |

| MARMOX Heavy Board PRO 15 – flat | 10 mm + 5 mm Mörtel | 600 | 1.250 |

| MARMOX Heavy Board PRO 14,5 – groove | 6 mm + 8,5 mm Mörtel | 600 | 1.250 |

| MARMOX Heavy Board PRO 18,5 – groove | 10 mm + 8,5 mm Mörtel | 600 | 1.250 |

other dimensions upon request

Installation

01. The substrate should be levelled, oil- and dust free, dry and stable. It’s important to install the edge insulating strips carefully. A primer need to be applied upon request. We recommend to use a flexible cement based tile adhesive, comb out with a 10 mm trowel creating a ribbed adhesive bed. The boards have to be fully bedded to ensure no void under them. MARMOX Heavy Board Pro have to be glued with staggered joints, the additional mortar layer on top.

02. When the adhesive is cured, apply the glass fibre mesh to the joints, embedded into flexible tile adhesive.

03. The floor is ready for tiling or application of self levelling compound after laying of heating wires.

04. Ready for the application of flooring material (e.g.: vinyl flooring, tiles, carpet, laminat)