MARMOX Board PRO – VBR –

breathable

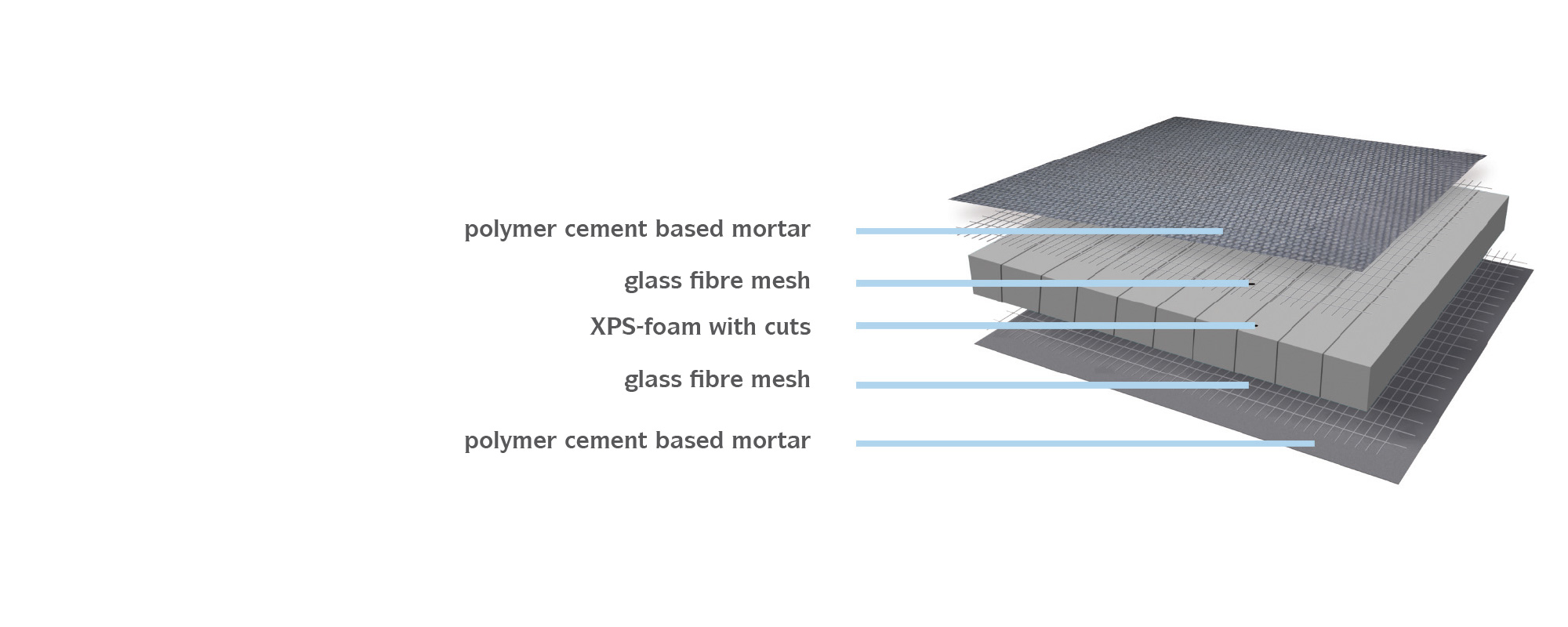

MARMOX Board PRO – VBR – breathable are made of a closed cell CFC and HCFC free polystyrene foam (XPS) as the core. The surfaces are coated with a cement based special mortar, reinforced with glass fibre mesh.

The characteristic of MARMOX Board PRO – VBR – breathable are cuts through the XPS foam in accurately defined distances to improve the breathability of the board. The number of cuts are in direct relation to the value of breathability. One main advantage is the lower water absorption of the board compared with other insulation materials, which is in direct relation to the long term value of heat insulation value.

MARMOX Board PRO – VBR – breathable are especially designed for applications where a long term water and humidity resistant heat insulation system with improved breathability is required (e.g. weather exposed building facades).

Properties

![]() high compressive strength

high compressive strength

![]() excellent breathability, compared with standard XPS-foam (e.g.: sD=1.6 m for 50 mm thickness acc. to DIN EN 12086)

excellent breathability, compared with standard XPS-foam (e.g.: sD=1.6 m for 50 mm thickness acc. to DIN EN 12086)

![]() light weight

light weight

![]() water and humidity resistant

water and humidity resistant

![]() waterproof under the condition of zero water pressure

waterproof under the condition of zero water pressure

![]() zero capillary

zero capillary

![]() fire rating class E, DIN 13501 – 1

fire rating class E, DIN 13501 – 1

MARMOX Board PRO – VBR – breathable are easy to cut on size by cutter or saw. The fastening can be done with glue, either applied on the full surface or alternative with dabs of glue. The boards have to be laid in a staggered pattern, aligned vertically and horizontally. Once the tile adhesive cured, drill the holes into the wall at the dabs position, insert dowels, washers and screws/nails. Cover all joints and washers with glass fiber mesh or sealing tape, embedded in a layer of flexible glue.